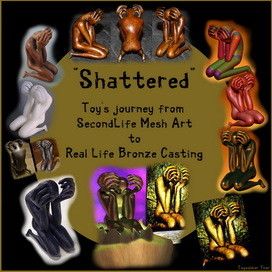

This is his bronze casting journey. Toy will also announce his plans for a second bronze casting of Shattered at a lower price. Now for those of you that missed the first casting, you can register here to be part of the next casting!

(click to enlarge)

(click to enlarge) In order to validate the viability of producing this art for Toy's art followers, he first engaged in a marketing campaign within all his social networks to see if anyone would purchase this bronze cast at a price that would not be a financial loss. He needed a minimum of five pre-orders to proceed. Toy was so excited when ten customers pre-purchased. He was more excited when the first customer to step up and invest in this project was none other than Ebbe Altberg, CEO of Linden Lab Inc.

By February Toy had more than enough customers to proceed. He received a financial commit from each of his customers to lock in the orders and it was time to start the heavy lifting of producing the actual bronze casts and getting them to each of Toy's customers' hands. How was this done?

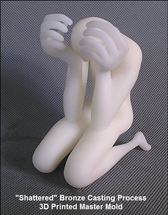

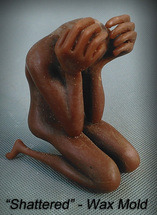

Toy initiated the 13 bronze edition casting with the Chinese foundry in early March 2015 by sending them an email with his 3D digital model export STL file. The foundry first 3D printed Toy's art model into a plastic master model. This would be used as input to the old traditional "Lost Wax" bronze hot poured casting method. The master mold is used to create the rubber molds sections. These rubber negative molds are used to create 13 editions of positive wax models. Each wax mold is actually a hand assembly of multiple wax parts that came from the rubber molds since a single rubber mold could not be used (it wouldn't be able to get the wax model out). The artisans carefully assemble an re-shape each wax mold to best match it to the master mold.

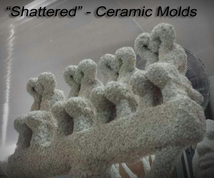

The wax models are then mounted to a wax manifold and pouring/venting ports. The entire wax assemblies are then dip coated with several layers of ceramic slurry and silica sand until the right thickness is achieved. This process takes a long time since each ceramic coating requires a full day of drying. The resulting ceramic negative molds are then baked at extreme temps creating a fragile but very heat tolerant mold for the bronze. At the same time the original wax burns off (hence "lost wax").

You can see the photos below of three of the phases just mentioned (click to enlarge).

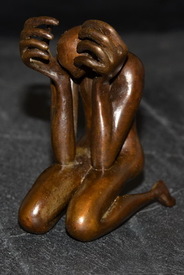

After cooling, the ceramic mold is shattered (pardon the pun) away from the raw bronze cast editions. They are each hand chased (making minor repairs to the bronze and closing the pouring holes) and then hand polished to the desired smooth surface.

In this form the bronze casts are in their natural shiny gold like color. If this was the desired color, the bronze would be surface sealed with wax. You can see the 13 casts editions in this gold-like stage in the photo below.

Each of the editions are then hand polished again to created the desired reflective sheen. A wax is applied and polished onto the bronze surface which protects the bronze colored surface.

The Chinese foundry then shipped these carefully packed editions by air freight back to me (at a pretty high shipping cost because of the weight - ~ 20lbs - and being air transport). Thankfully even though the shipment came from China, bronze cast art has almost no duties. Therefore the customs / brokerage fees were relatively lower than I feared.

The foundry did a pretty good job final polishing each of them, but Toy still saw some wax film on the very hard to reach nooks and crannies of each of them. So Toy spent 3 hours hand buffing them with a tea towel to get them to the best polish he could reach. The result is similar to the photos you see below of one of them.

Toy also needed to create an official Letter of Authenticity for each owner to acknowledge this as a first bronze casting and that they were the first registered owners of these 10 editions. Each casting has Toy's artist initials followed by a "1" under the left leg to identify the edition as being a first casting. The letter also takes time to explain the artwork's meaning as well as the importance of this being the first ever casting for him and likely SL. Toy printed these letters on heavy 65lb parchment paper and sent these letters under separate cover to avoid folding.

WHAT NEXT ? PLAN THE SECOND CASTING RUN !

The reaction from several of those that have already seen the bronze cast results has been very positive! There has already been several inquiries on how they could buy one of them - which of course all of the first casting was accounted for. But because of this early demand Toy is already planning a second and hopefully larger casting run.

The first casting had a final price of $155 US plus shipping to the customer. This was to cover the higher initial costs that a first casting incurred (3D printing of the master mold and creation of the rubber molds). Also, as is well known, there his a higher market value applied to any 1st casting / print / edition of an artwork. The first casting price reflected these two important factors.

As such, the price for the second casting of Shattered is targeted at $110 US plus shipping

If you are interested in being a part of my second Shattered Casting Run, Toy has created an entry form below where you can register to be part of his second casting run when he initiate it - hopefully in early summer or sooner.

RSS Feed

RSS Feed